Sandow Technic,

specialists in customised elastic cords, straps and nets

A company always focused on new challenges

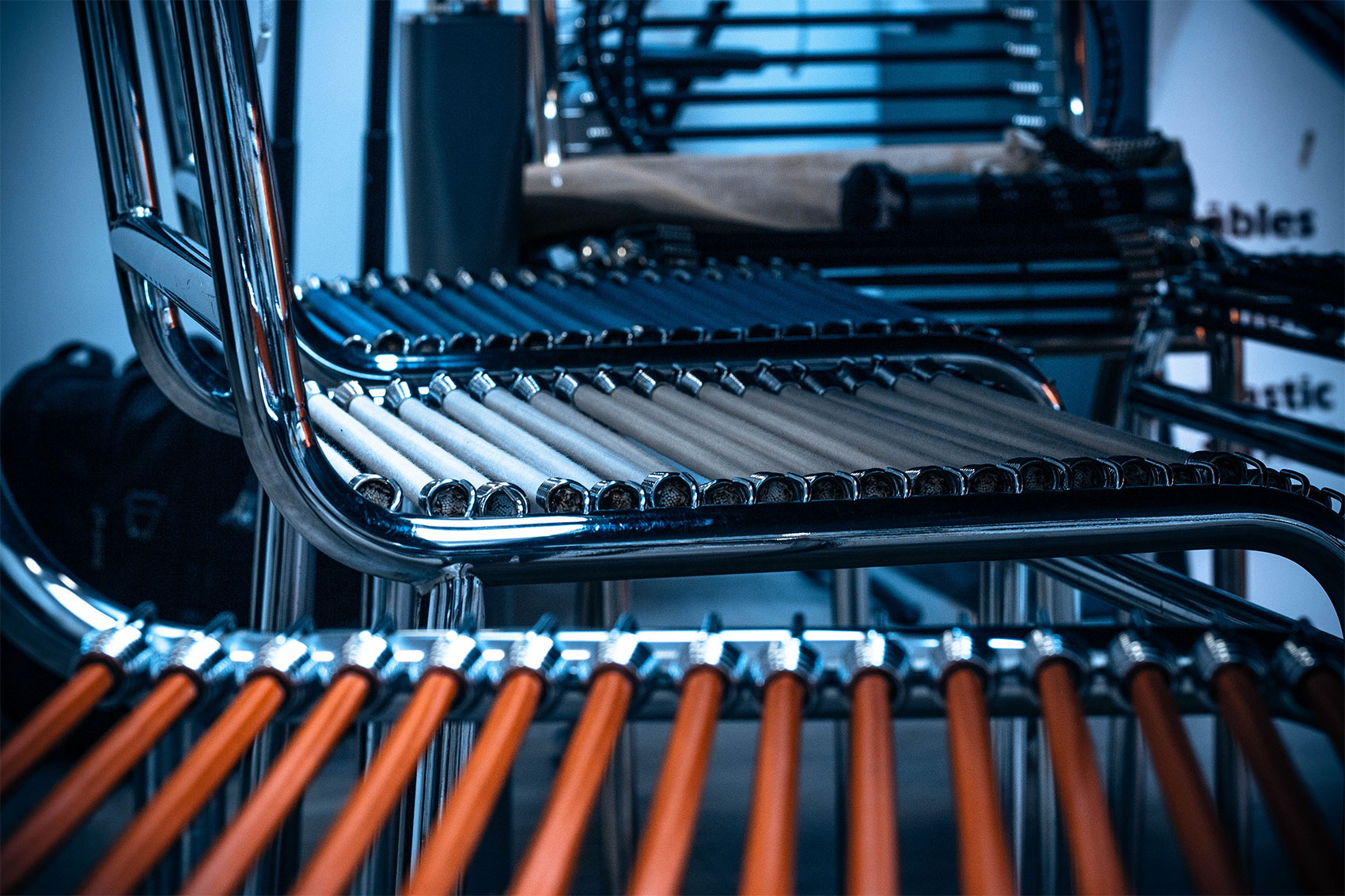

Created in 1963, Sandow Technic specialises in manufacturing industrial elastic cord of 1 to 40 mm in diameter, customised straps and nets.

In 50 years of existence, SANDOW has become a leader in its field. We work with companies from a wide range of sectors, including aeronautics, automobile, sport, civil and military aviation, armaments, general mechanics, industry, maritime work, naval work and today we have real expertise in this market and recognition as a specialist in elastic cords, straps and nets for industry.

Our collaborations with designers, laboratories, suppliers of materials, regulatory committees, test centres, study centres, etc. have helped to make SANDOW TECHNIC what it is today, a company focused on innovation.

Our elastic cords, straps and assemblies have been associated with some of the most famous projects and names: AIRBUS (EADS), Dassault, SNCF, Thalès, EDF, CEA, Renault, Zodiac, etc.

50 years of history

Some major events have marked the development of SANDOW TECHNIC

The development of a range of elastic cord compliant with standard ASNA 0243 for use in aeronautics, the AVIA shock cord range has become a benchmark product in terms of quality.

Adapting this range to the industry sector in general and producing customised assemblies compliant with international standards such as B.S. (British Standards) or the American U.S. MIL and technical standards such as FAR 25.853, ABD0031, FMVSS 302, ECE R16, etc., has given the company its international dimension.

SANDOW TECHNIC is still today the only company in France to supply industrial shock cords, and notably shock cord rings for aeronautics and other industries. Subsequently, we wanted to gain a better understanding of the needs of different sectors and to be aware of the market and the needs of SMEs, and so SANDOW TECHNIC went on to develop real expertise and create a range of products adapted to the needs of our customers. About 20 years ago, we also diversified our activity and launched a new range of products, moving into straps, and more recently extending our expertise to nets in order to meet customer requirements.

New technical product ranges using special polymers have also emerged in an increasingly standardised, demanding and changing market.

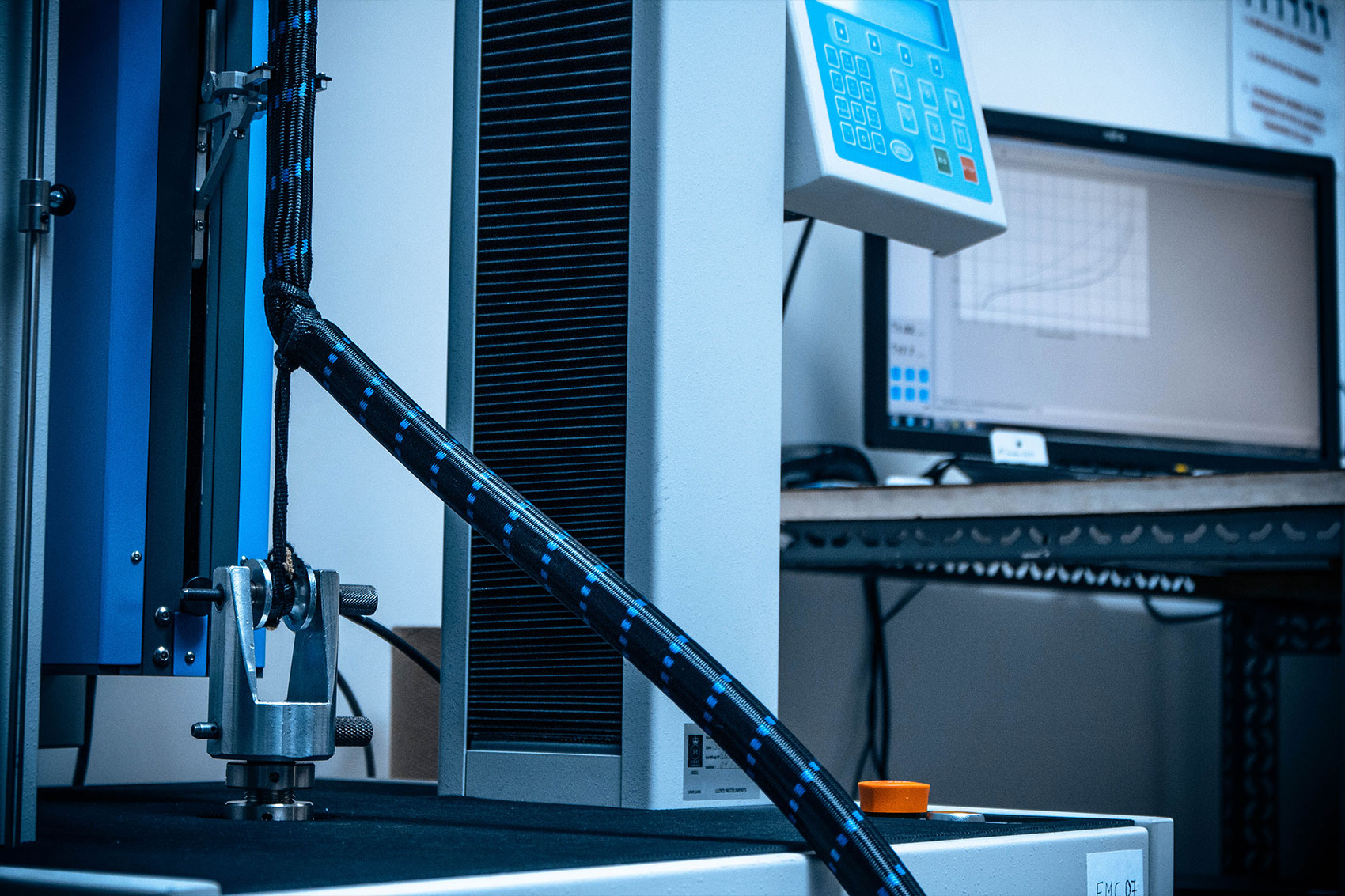

SANDOW TECHNIC, producer of shock cords, straps and nets, is ISO 9001:2015 certified with EN 9100 certification underway.

50 years of history

Some major events have marked the development of SANDOW TECHNIC

The development of a range of elastic cord compliant with standard ASNA 0243 for use in aeronautics, the AVIA shock cord range has become a benchmark product in terms of quality.

Adapting this range to the industry sector in general and producing customised assemblies compliant with international standards such as B.S. (British Standards) or the American U.S. MIL and technical standards such as FAR 25.853, ABD0031, FMVSS 302, ECE R16, etc., has given the company its international dimension.

SANDOW TECHNIC is still today the only company in France to supply industrial shock cords, and notably shock cord rings for aeronautics and other industries. Subsequently, we wanted to gain a better understanding of the needs of different sectors and to be aware of the market and the needs of SMEs, and so SANDOW TECHNIC went on to develop real expertise and create a range of products adapted to the needs of our customers. About 20 years ago, we also diversified our activity and launched a new range of products, moving into straps, and more recently extending our expertise to nets in order to meet customer requirements.

New technical product ranges using special polymers have also emerged in an increasingly standardised, demanding and changing market.

SANDOW TECHNIC, producer of shock cords, straps and nets, is ISO 9001:2015 certified with EN 9100 certification underway.

A highly qualified and specialised team ready to work on your projects

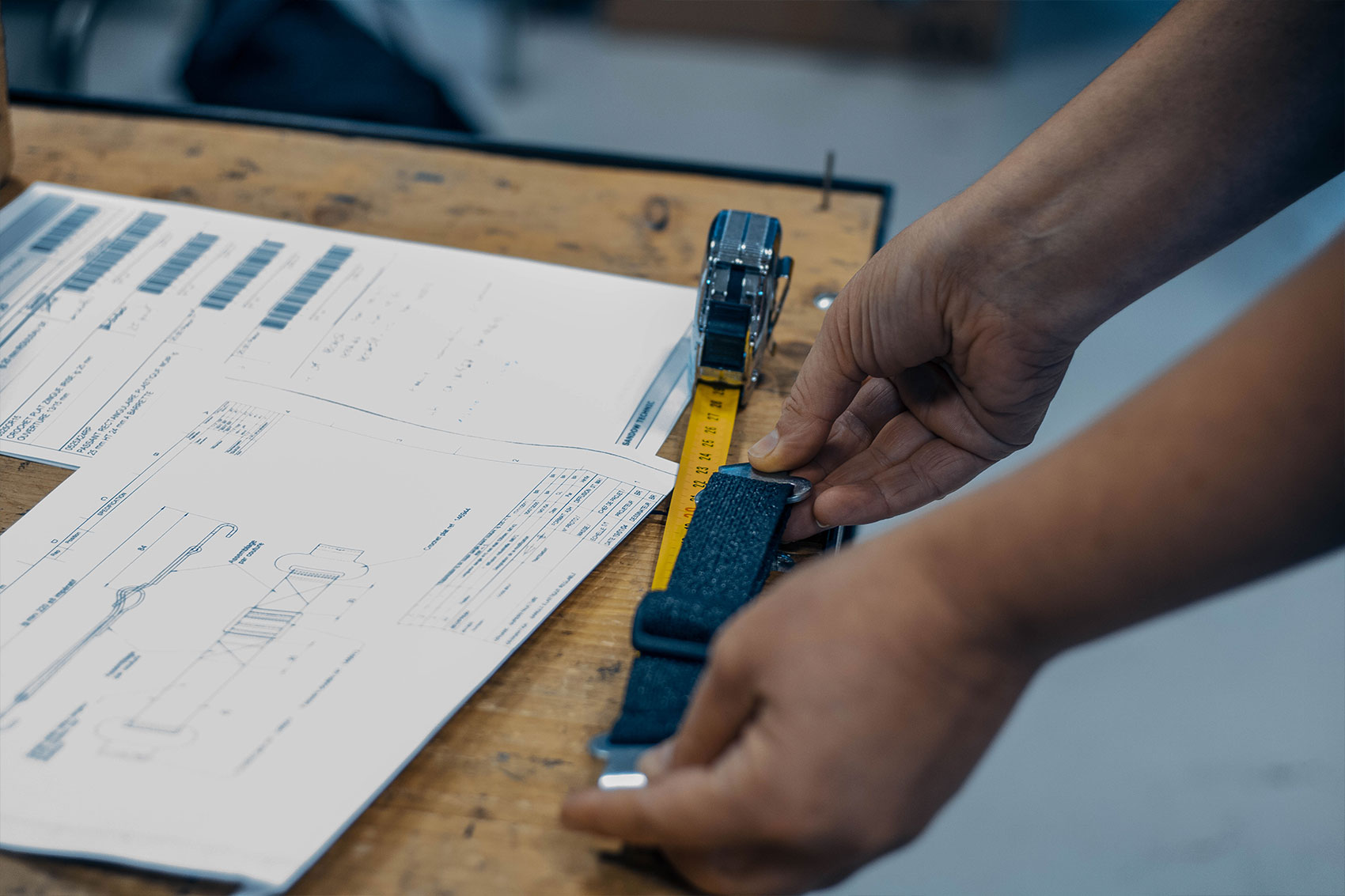

One of the key factors in the success of our workshop is our multi-skilled and versatile team. Production and quality are intrinsically linked in our processes, ensuring technical skill at all stages of design and manufacture.

Our teams’ know-how and experience ensure that requirements for the high technical standards, performance and quality of our product ranges are met.

Today, one of the greatest problems the industry faces is that of knowledge transfer. Our employees regularly attend continuous training courses to ensure the sustainability of our know-how and meet customers’ ever-increasing demands.

Developing new skills, discovering new crimping and seam techniques to offer better resistance to tearing, linearity under extreme conditions of use, and “self-liberation” all lie at the heart of our industrial aims.